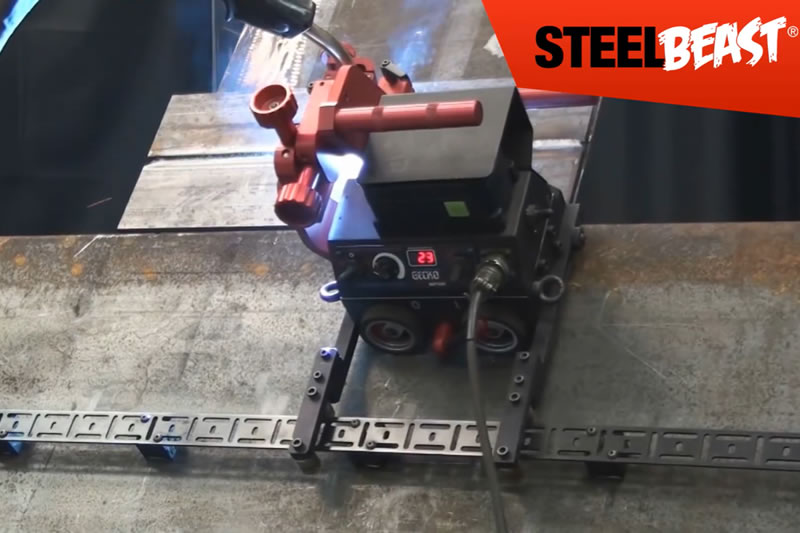

It was great to see Daver Steels Ltd continuing to invest in new processes and equipment. We were pleased to demonstrate the Gecko Battery welding tractor with dual torch holder to their team, helping them explore automation for welding 3m I-beams. The results? Faster speeds, improved weld quality, and reduced operator fatigue. JEI is proud to be part of Daver Steels continued investment in the future of fabrication.

The Gecko Battery 2 is a carriage designed to weld continuous butt and fillet joints. The carriage is battery-powered. The carriage allows MIG/MAG torches and is clamped with permanent magnets. Accessories allow using torches with a larger diameter and using two torches at the same time.

They also allow the carriage to move along outside edges, lap joints and templates, walls that are low or have holes, and on ceilings, pipes, and tanks. Using an optional flexible trackway set allows the carriage to move on a flexible rail. You can clamp the rail to the surface by using magnetic units or by using vacuum units and a vacuum track system.

Usage & Benefits

The Gecko Battery with dual torch capability is particularly useful when you have:

- Long continuous welds where travelling manually is slow and inconsistent.

- Fillet welds or butt welds where high quality and repeatability are important.

- Situations where the carriage portability is valuable (battery powered, less cable clutter).

- Jobs where deploying dual torches makes sense (e.g., welding both sides of a T-joint, or welding two seams simultaneously to reduce cycle time).

- Out-of-position welding (vertical/horizontal) because of magnetic traction and four-wheel drive.

- Improved weld consistency (due to mechanised travel).

- Reduced filler metal waste / less over-welding because travel speed is controlled.

- Operator fatigue reduced (less manual travel to manage).

- Higher productivity, especially when dual torches are used.

The JEI range is further enhanced by the Steelbeast® range of fabrication solutions, designed to prepare steel for further processes, with a complete range of solutions for plate and pipe bevelling, punching, sawing, grinding and weld automation.

JEI customers are supported by our highly experienced sales team and technical and service personnel. Our knowledgeable team provides exceptional customer service and is always on hand to assist in finding the perfect solution for your project needs, whether you are based in the UK or elsewhere. Please contact us at sales@jeisolutions.co.uk or call +44 (0) 1706 229490 to discuss your requirements.

#JEI #JEISolutions #Bevelling #Welding #Drilling #Cutting #AutomatedWelding #SteelFabrication #SteelBeast #Innovation #Investment